The Intricacies and Importance of Diecasting in Modern Manufacturing

The Intricacies and Importance of Diecasting in Modern Manufacturing

Blog Article

Diecasting is one of the most important processes for modern manufacturing. It plays the most important role in making intricate metal components with accuracy and efficiency. It involves pushing molten metal under high pressure into a mold cavity which results in components that have exceptional dimensional accuracy and high finish on the surface. In the midst of a rapid growth in industries, and as demands for quality components rises, diecasting has continued to be a valuable tool specifically in the areas that require large-scale production of complex parts. This article delves into the diecasting process along with its pros and cons, various material choices, and its extensive uses across many industries.

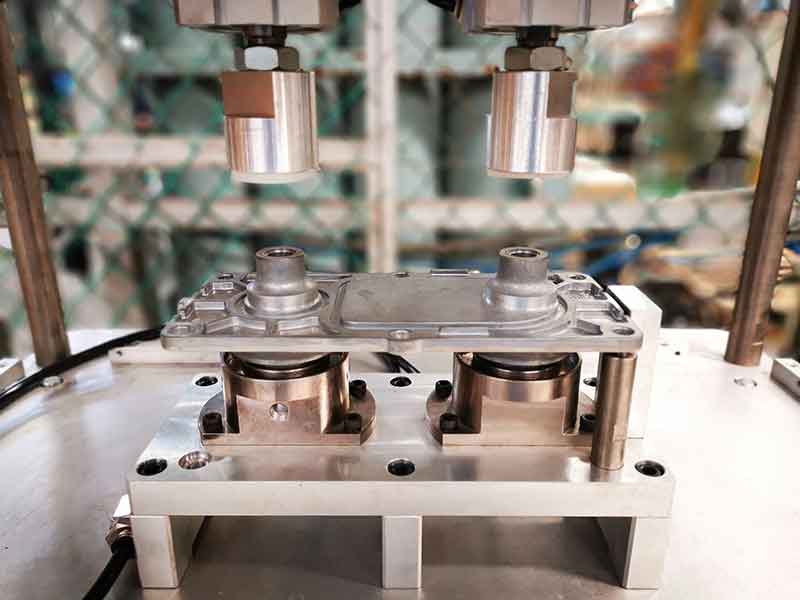

Diecasting begins with the creation of a mold, also known as a "die," which is made of hardened steel for a long time to endure high pressures and temperatures. When the mold is made metal alloys, such as magnesium, aluminum, zinc, or copper are heated to the point that they turn molten. The molten metal then gets injected into the die at the highest pressure to ensure it is able to fill all areas of the mold including intricate segments and the thin walls. This pressure will be maintained until the molten metal is solid, when the die opens, and then the newly created part is then ejected. The process is high-pressure, which ensures the finished product is accurate and requires no further machining or finishing.

One of the major advantages of diecasting is the ability to manufacture parts with incredible dimensional precision and flawless finishing on surfaces. Diecasting with high pressure ensures each and every aspect of the mold is replicated, resulting in parts with tight tolerances, and need minimal or none post-production tasks. This accuracy is particularly useful for creating complex geometries and specific details that may be difficult to attain with other manufacturing techniques. Also, the repeatability of diecasting allows it to be used for large-scale production, ensuring that the exactness of thousands of pieces. The effectiveness of this process can also result in significant cost savings, as it can reduce material waste and labor costs.

Diecasting can also provide significant advantages with regard to mechanical properties. Components produced through diecasting typically offer excellent strength and endurance because of the fine-grain structure that is formed by the quick cooling of the molten metal. These components are perfect for use in applications that require top performance and dependability. Furthermore, this process permits to integrate thin walls and complex elements without compromising the structural solidity. This can be particularly beneficial when it comes to aerospace and automotive sectors, where the ability to reduce weight while maintaining strength is critical. A capability to manufacture extremely light and strong components can improve the efficiency of fuel and the performance of vehicles and aircraft. To acquire added information kindly go to https://www.senadiecasting.com.my/

Diecasting's flexibility extends beyond the mechanical advantages to its flexibility in a variety of areas. For electronics, diecasting is used to create enclosures, heat sinks, connectors, and enclosures which ensures that equipment is protected and function perfectly. This process is used to create everyday goods, from kitchen appliances to power tools where precision and durability are paramount. Diecasting is a process that can produce detailed and intricate parts is a draw for engineers and designers who want to create new ideas and increase product capabilities. By accommodating a range of metals and allowing for the integration of features that are intricate, diecasting supports the development of advanced products across multiple fields.

Diecasting is a highly productive and flexible manufacturing method which is essential to the production of sophisticated metal parts with extreme precision and consistent. Its capacity to design parts with intricate details as well as tight tolerances and smooth surface finishes makes it a valuable tool in a variety of sectors, from automotive to aerospace, to consumer electronics, and beyond. Different materials further enhances the versatility that diecasting offers, allowing companies to select the ideal alloy to suit their requirements. With the advancement of technology and as the demand for premium, efficient components grows and increase, diecasting will continue to be an essential element on the manufacturing scene that drives innovation and quality in the field of production.